The world’s first Wi-Fi 6 USB 3.0 adapter delivers AX1800 speeds with advanced features such as OFDMA, MU-MIMO and WPA3™ network security. World’s first Wi-Fi 6 (AX) USB 3.0 dongle AX1800 Speeds up to 600 Mbps (2.4 GHz) / 1200 Mbps (5 GHz). China Usb Device wholesale - Select 2021 high quality Usb Device products in best price from certified Chinese Usb manufacturers, Usb Stick suppliers, wholesalers and factory on Made-in-China.com. The first thing to do is connect your j-link (Mbed Studio probably supports other programmers, but this is all I have) and select that as the USB device. Then on the build target you'll need to click on the button to the right so you can create your own customtargets.json where you can then define parameters for your chip (or board). Quality Laser Control Application - LaserCut 5.3 Operation Software - find quality Accessory and Software, Laser Engraving Machines & Accessory and Software from Leetro Automation Co., Ltd. Of China Suppliers - 110970263.

No the key switch or PLC mode does not matter to RSLinx or RSWho.

No the key switch or PLC mode does not matter to RSLinx or RSWho.

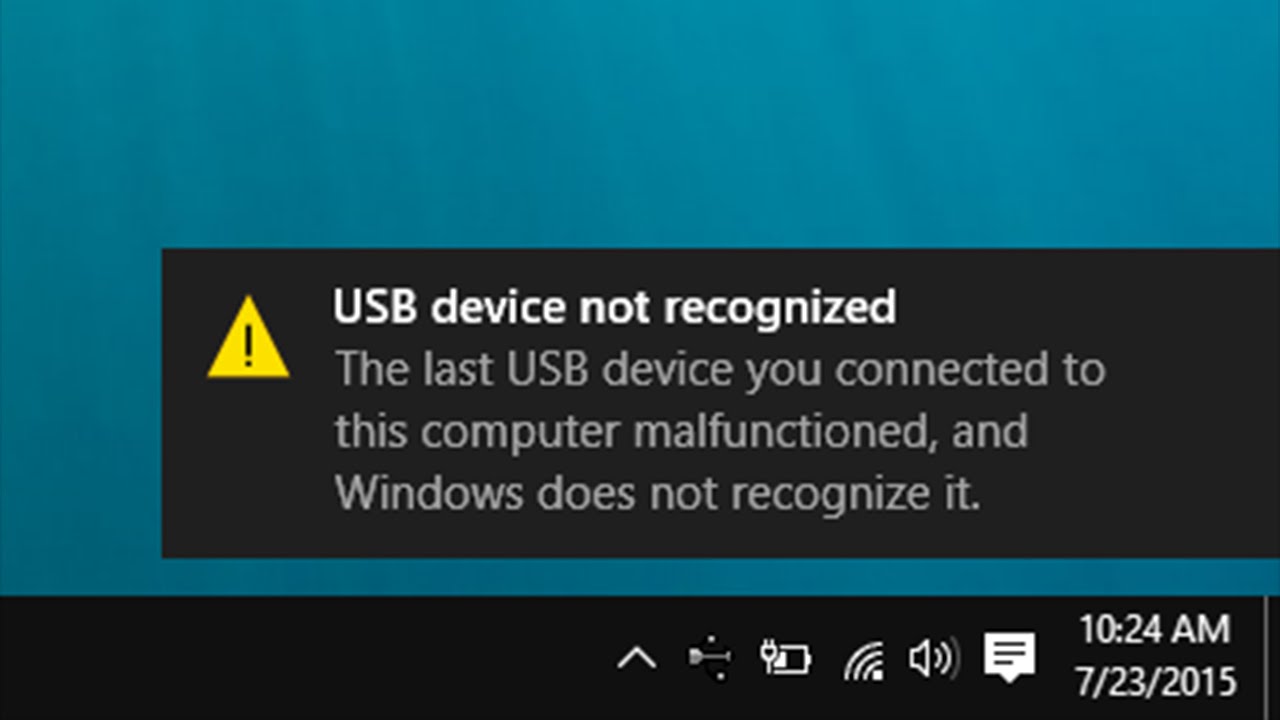

Usually when you plug in a new device through USB you hear Windows 'ding' as it detects the hardware. Are you getting that sound as you plug and unplug the USB cable?

I have also had issues with Windows 7 and USB 3.0 ports. USB 3 is not natively supported in Win7 so the right drivers are critical. I've had machines that would see my device, but when I unplug it locks up the USB port. So plugging and unplugging had no effect. I had to reboot to get it to see the connection. I moved my machines to Win10 where USB 3 is natively supported and those issues went away.

Anyway....a couple suggestions.

- Try a different USB port. Avoid the USB 3.0 ports. Typically these are either blue or they are labeled as 'SS' for SuperSpeed. At least that's how Dell labels them.

- Delete your USB drivers from the Windows Device Manager. Go into the Device Manager and Universal System Bus Controllers and uninstall (don't delete files) any Intel or other branded drivers. Don't worry about the 'generic' or 'Root Hub', as they will delete automatically. After uninstalling right-click and select 'Scan for hardware changes' and those devices will all reinstall.

- Delete the Rockwell Automation USB CIP Device from the Device Manager. Plug the cable back in and it should reinstall.

- Do a Windows Update. New USB drivers may be available. If for some reason you did not have the proper USB CIP driver, Windows Update will get it for you.

OG

- Leetro Automation Co., Ltd.

- China Manufacturer with main products:motion controller ,stepper driver ,servo driver ,servo motor ,stepper motor

- Product Categories

- Company Profile

Home>Products>Accessory and Software>Laser Control Application - LaserCut 5.3 Operation Software

- Share|

- USD $89 - $134 / Piece|Get Latest Price

- 1 Piece / Pieces

- 100 Piece / Pieces per Month

- Chengdu

- MoneyGram Credit Card PayPal

| Condition: | New | Laser Type: | CO2 | Engraving Area: | 1300*900mm |

| Engraving Speed: | 1000mm/s | CNC or Not: | Yes | Cooling Mode: | Air Cooling |

| Applicable Material: | Acrylic, Crytal, Glass, Leather, Metal, Paper, plastic, Plywood, Rubber, Stone, Wood | Graphic Format Supported: | AI, BMP, DST, DWG, DXF, PLT | Place of Origin: | Sichuan, China |

| Brand Name: | Leetro | Model Number: | LaserCut5.3 | Dimension(L*W*H): | 55*18*8mm |

| Certification: | ISO | After-sales Service Provided: | Overseas service center available |

cartons/bags

This Software is for Leetro's laser-dedicated controllers exclusively

LaserCut software developed by Leetro Automation Co., Ltd. It is applied to laser engraving and cutting system based on MPC03, MPC6515 or MPC6535.

Main features:

* Seamless connection with CorelDraw and AutoCAD makes the operation much easier.

* Supports data formats such as AI, BMP, PLT, DXF, DST (Tajima Software).

* After graphics & image data being called in, the system will carry out simple makeup and edit (such as zooming, rotating, reproducing and so on)

* The software can hierarchically output data and easily set the output power, output speed and output mode (engrave, cut, and so on) and automatically save the defined parameters of every layer.

* The software can engrave the image, scribe, cut and engrave the vector diagram and set engraving precision.

* The software supports array output and can automatically distribute the array to the entire workbench. The software can also display output effect through analog output. The origin location can be defined at random to facilitate processing.

* Pause and Continue are available during output and all output control operations can be directly connected to the operational control panel of devices for easy operation.

* The software provides frame-tracing function during output so as to easily find the discharge location.

Engraving speed can reach 1500mm/s, curve cutting speed can reach 500mm/s and engraving precision can reach 0.1mm.

* 360 degree slope engraving. The slope can be freely set and there is no limitation of speed (subject to the laser processing depth).

* High processing speed of large data & graphics. Data of 15M less can be processed for an instant.

* Constant laser processing strength during high-speed cutting ensures consistent processing depth.

* Optimized Cutting path. Customers are provided with various path optimization methods.

* Derivate lines can be introduced when cutting to ensure the smooth and flat cut seaming.

* Unique breakpoint processing function ensures that no rejected product will be produced even when power is suddenly cut.

Outstanding features compared with laser engraving like products:

* Advanced Position Compare Output Iron out the deviation problem in speedy engraving. The engraving speed is 90m/min, leading the like products.

* Distinct Look-Ahead Algorithm And Track-Fit Algorithm highly enhance the operating efficiency. Speed for cutting circles reaches 30 m/min, leading the laser processing industry.

* Advanced Synchronous Tracking Control Ensure the synchronous changes of the laser power and the speed of laser head's moving.

* Advanced PWM (Pulse-Width Modulated) Control Implement 360 degree slope engraving easily, increase the real-time capability in adjusting the laser power.

* No distortion in speedy cutting roundlet

DHL, TNT, FedEx air express

12-month product warranty

- Leetro Automation Co., Ltd.

- ContactAndy Liu

- Phone86-28-85142599

- AddressBldg. 8-B, Dayi Incubation Park, No. 1, Keyuan South 2nd Road, New and Hi-Tech Zone Chengdu,Sichuan

| Accessory and Software | Motion Controller | New Products | Power Supply |

| Stepper Driver | Stepper Motor |

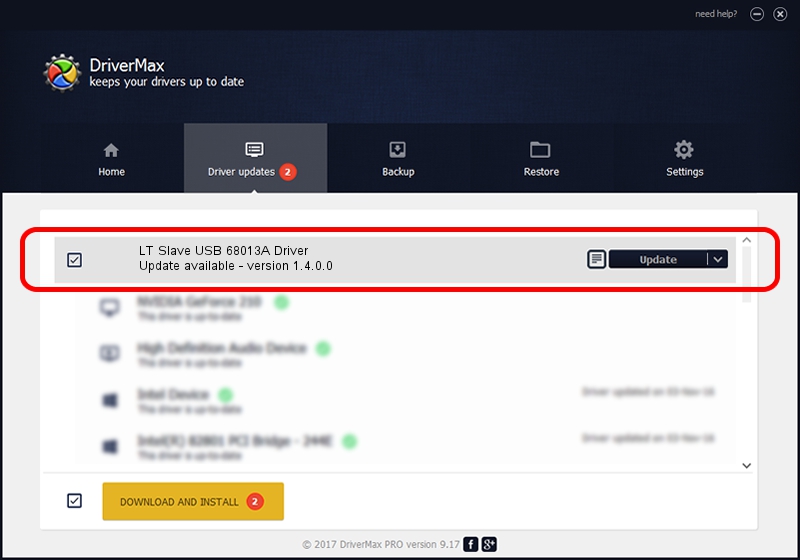

Chengdu Leetro Automation Usb Devices Driver Windows 7

- 120T Hydraulic Leather Upper Embossing Machine

- 50T Hydraulic Leather Upper Embossing Machine

- 30T Hydraulic Leather Upper Embossing Machine

- 2 Meters Automatic Leather Meauring Machine With Printing

- 16T Hydraulic Leather Upper Cutting Machine

- 12T Hydraulic Leather Upper Cutting Machine

- Automatic Shoe Back Parts Molding Machine

- Road hair dryer RWCF12

- Road hair dryer RWCF11

- 200SV-SP Vertical Slurry Pump

- Tobee® TJL Vertical Sump Pump

- 300TV-SP Vertical Slurry Pump

Chengdu Leetro Automation Usb Devices Drivers